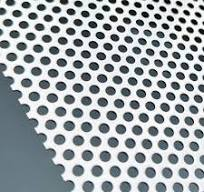

Stainless Steel Perforated Sheet is now an essential material in many fields of modern engineering and architecture. These sheets have holes that were punched with great care, which makes them strong and good-looking. Professionals who need strength, durability, and design flexibility prefer them for facades, filtration systems, acoustic panels, and HVAC parts since they can be used in so many different ways. The perforations are always in the same place, which makes for better ventilation, drainage, and weight loss without losing strength.

Why Use SS 316 Perforated Sheets in Tough Situations

SS 316 Perforated Sheets are better than other types of stainless steel because they are more resistant to rust and wear and tear. SS 316 is made mostly of chromium, nickel, and molybdenum, and it stays strong even in acidic or chloride-rich situations. This makes it perfect for use in the marine environment, in chemical processing, in pharmaceutical installations, and in outdoor constructions that are exposed to changing weather conditions. Industries choose SS 316 to ensure that their installations can handle time, moisture, and chemicals, which lowers maintenance costs over time.

The main benefits of stainless-steel perforated sheet are that make it a popular choice

Many industries still buy SS 316 Perforated Sheets or their conventional stainless-steel versions because they offer a lot of different benefits. These include great tensile strength, limited thermal conductivity, and a very high resistance to rust and heat. Stainless steel is also clean and easy to clean, which makes it good for hospitals, food processing, and labs. The holes not only make the material lighter, but they also help with ventilation and sound absorption, which improves performance in a wide range of industrial and architectural situations.

A stainless-steel perforated sheet makes buildings look better.

Modern architecture often combines usefulness with beauty. Stainless Steel Perforated Sheet is great at this. Architects use it for building facades, sunscreens, and partition walls to give them a sleek, industrial look while making sure they work. These sheets come in a variety of hole sizes, designs, and finishes, giving you a lot of creative freedom while still being very strong. Their effect is both structural and artistic, whether they are backlit in a store or utilized as cladding on public buildings.

How SS 316 Perforated Sheets Are Used in Industry

SS 316 Perforated Sheets are used in industries where conditions are quite harsh, such as petrochemical factories and wastewater treatment plants. They can work well in places where other materials would break down because they can resist seawater corrosion, acidic media, and high temperatures. Also, their structural stability lets them be made into filters, screens, guards, and support structures, which give important support without bending or getting tired.

Conclusion

Adding Stainless Steel Perforated Sheet and SS 316 Perforated Sheets to structural and design projects gives you a great mix of style, performance, and durability. These sheets are made to exceed expectations in all fields, from improving modern architecture to making industrial machines stronger. Professionals all over the world favor these materials because they are resistant to corrosion, flexible in design, easy to maintain, and good for the environment. Dinco.ae has a huge collection of high-quality SS 316 and stainless-steel perforated sheets that are made to fit a variety of project demands. These sheets are a good choice for people who want to invest in quality and durability.

Frequently Asked Questions (FAQs)

Q1: What makes SS 316 Perforated Sheets different from SS 304?

SS 316 includes molybdenum, which enhances corrosion resistance, especially against chlorides and marine environments, making it more suitable for chemical and outdoor applications.

Q2: Can Stainless Steel Perforated Sheet be customized?

Yes, these sheets can be tailored in terms of thickness, hole size, pattern, and dimensions to fit specific industrial or architectural requirements.

Q3: Are SS 316 Perforated Sheets suitable for high-temperature applications?

Absolutely. They offer excellent heat resistance and structural stability, making them ideal for processes involving extreme temperatures.

Q4: Where can these perforated sheets be used aesthetically?

From decorative panels, acoustic walls, to modern façades and ceiling designs, Stainless Steel Perforated Sheet enhances both beauty and functionality in design projects.

Q5: Why is it advisable to buy SS 316 Perforated Sheets for marine environments?

Their superior corrosion resistance ensures long-lasting performance and low maintenance, even when exposed to saltwater or chemicals.